Manesar, Gurugram, Haryana

- GST NO. : 06AAFCC0655B1Z8

View Mobile Number

Audit Services

Leading Wholesaler of C TPAT Audit Services in India, C-TPAT Security Audit Services, Construction Safety Audit Services, Electrical Safety Audit Services, Factory Compliance Audit Services, Fire Safety Audit Services, GDP Audit Services in India, GHP Audit Services, GMP Audit Services, Green Audit Services in Sonipat, Health and Safety Audit Services, Industrial Safety Audit in India, Industrial Safety Audit Services, Supplier Audit Services, Supply Chain Audit Services, Workplace Health and Safety Audit in India and Workplace Safety Audit in India from Gurugram.

CDG Inspection Ltd provides C TPAT audit services from Gurgaon, Haryana. CBP examines the provided materials once the application and supply chain security profile has been completed satisfactorily. The CBP C-TPAT program will then have up to 90 days to either certify or reject the company's application. The firm will be verified within three years after certification if it is certified.

C-TPAT (Customs-Trade Cooperation Against Terrorism) is a voluntary, public-private partnership that aims to improve supply chain security and border security-TPAT stands for Customs-Trade Partnership Against Terrorism and is a US Customs and Border Protection (CBP) project. C-TPAT is a volunteer initiative in which members seek to prevent terrorist weapons, especially weapons of mass destruction, from being hidden in supply chains.

C TPAT was established in November 2001 in response to the September 11 terrorist attack in New York. It is a voluntary incentive-based program where partners work with members of the trade community to strengthen global supply chain security and prevent the supply chain from being compromised by terrorist organizations.

The C-TPAT requirements are a set of guidelines that the US Customs and Border Protection (CBP) agency has provided to the US Customs and Border Protection. They are designed to help companies understand what they need to do to comply with the CTPAT program.

What Is C TPAT Compliance, When it comes to CTPAT compliance, it is important your business have all the correct documents.

CTPAT Documentation for Personnel

You must have a contract with employment agencies that includes background screenings including DMV, FBI, and export control screenings. As proof of the screening process taking place at your company, you must keep a copy as evidence.

CTPAT Documentation for Business Partners

For business partners, you must review and screen your customer database, vendor/supplier database, transactional partners, and service providers. In addition, your foreign suppliers must complete and submit their CTPAT questionnaire to you and identify any weaknesses, have an improvement plan, and retain all such documents.

For IT and technology access, you can use your C TPAT manual alongside any technology control plans you may have for export control purposes. You must keep all documents, including a wide-aisle tour plan to avoid sharing any controlled technology with authorized people. Keeping proof of internal audits and reviews is a must to ensure all procedures are in place and being followed.

For physical access, you should keep card swipe records near your CTPAT records, photos of security and barriers, copies of truck drivers’ licenses, videos of validation of those granted access to your facilities, and visitor procedures, and these records should be sealed in containers.

What Are the CTPAT Benefits?

As mentioned previously, the CTPAT program is a voluntary support program. But there are many benefits of joining this program, and these benefits can help your business overcome a range of challenges.

The benefits of the CTPAT program include:

Playing an active role in the war against terrorism.

A reduced number of CBP inspections.

Priority processing for CBP inspections.

Eligibility to attend C TPAT training lectures.

Prerequisite for participation in the importer self-assessment program.

Penalty mitigation under certain circumstances.

Assigned a security consultant and a supply chain specialist.

Tier III importers allowed block designation application to DHS Safety Act.

Exporters who allow CBP to share information with other customer agencies gain reduced inspections upon arrival in certain countries.

Access to Free and Secure Trade (FAST) lanes at various land borders (Michigan, New York, Washington, and at southern border ports from California to Texas).

C-TPAT Security Inspection Customs-Trade Partnership Against Terrorism (CTPAT) is part of the U.S. Customs and Border Protection’s (CBP) multi-layered cargo enforcement strategy. Through this program, CBP works with the trade community to strengthen international supply chains and improve United States border security. CTPAT is a voluntary public-private sector partnership program that recognizes that CBP can provide the highest level of cargo security only through close cooperation with the principal stakeholders of the international supply chain such as importers, carriers, consolidators, licensed customs brokers, and manufacturers. The Security and Accountability for Every Port Act of 2006 provided a statutory framework for the CTPAT program and imposed strict program oversight requirements. International Associates Limited is able to carry out CTPAT audits for suppliers exporting goods into the USA. This program calls upon importing businesses and service providers to establish policies enhancing their own security practices and those of business partners involved in the supply chain, based on the following C-TPAT security criteria: Business Partners Requirements Container Security Physical Access Controls Personnel Security Security Training & Threat Awareness Information Technology Security Once these policies are given an effect, imports by these businesses would be given a “Fast Lane” by the US Customs.

Why CIL For C-TPAT Supply Chain Security Assessment?

CIL is an ISO 17020 accredited inspection agency for C-TPAT Supply Chain Security Risk Assessment of ICDs (Inland container depot), CFS (container freight stations), Terminal operators, warehouses, logistic providers, and foreign manufacturers. CIL is accredited by ANSI / ANAB. CIL has years of experience in supply chain security assessment.

What does a C-TPAT audit involve?

CIL’ iѕ a third-раrtу inspection соmраnу thаt саn аudit thе fоllоwing in rеlаtiоn tо C-TPAT:

• Container Security

• Physical Sесuritу

• Infоrmаtiоn Tесhnоlоgу

• Conveyance Security

• Phуѕiсаl Access Cоntrоlѕ

• Prосеdurаl Sесuritу

• Sесuritу Training and Thrеаt Awаrеnеѕѕ

• Business Partner Selection

Requirements for C-TPAT

The C-TPAT / CTPAT requires CDG to have documented procedures and policies to screen customers and for maintaining adequate security programs.

Some of the areas that are audited include

• Outside barriers and Physical Security

• Factory Security

• Computer Security

• Password controls

• Personnel security

CDG expertise in C-TPAT certification

1. The services we provide include ensuring the compliance of C-TPAT-certified organizations to the existing regulations.

2. CDG applies established methods and techniques in evaluating the required components. We are dedicated to guiding organizations towards C-TPAT participation by ensuring the security of their supply chain activities.

3. As part of CDG services, we also guide carriers, importers, and brokers in implementing the most secure measures for their supply chain activities.CDG's dedicated team is also involved in the validation of the required premises.

4. The Customs-Trade Partnership Against Terrorism (C-TPAT) is a supply chain security program led by U.S. Customs and Border Protection focused on improving the security of private companies' supply chains with respect to terrorism. This initiative was launched to assist the trading community in the war against Terrorism.

CDG Inspection Ltd in Gurgaon, Haryana believes in overall quality management and recognizes the importance of evaluating our current structures and ongoing infrastructure improvements for potential risks and non-conformance to quality standards. We are competent in doing on-site (3rd party audits) for our customers in compliment to 1st and 2nd party audits.

Our team conducts safety audits by reviewing the developer's design, design limit updates, requirements, testing-commissioning analyses, statutory authorizations, and related documentation. We also conduct a walk-through as well as a visual evaluation of the premises and building to establish a survey of the observations. After that, we recommend to the client on technical elements of the project, and score the overall effectiveness of the advancement in our construction safety audit services.

What is Construction Safety Audit?

Construction Safety Audit is an integral part of construction worker safety and is committed to providing a Safe Work Environment to every construction worker. The Construction safety audit is a review of a job site’s safety program, the site itself, and all the actions that are taken to prevent injury.

Why your Organization would require Construction Safety Audit?

Organizations would require Construction Safety Audit in order to attain the below benefits:

Comply with construction safety laws & regulations

Review the effectiveness of the H&S policy statement

Identifies all significant hazards & the people who are at risk from each hazard

Evaluate the existing risk control measures & determine required additional control measures

Examine the availability of a suitable emergency response plan detailing the responsibility & action of key personnel

Brings value to the workplace by avoiding prosecution, litigation, absence costs & loss of reputation

Reduced insurance premiums & indirect cost of workplace injuries

Fosters workforce morale & wellbeing

Enhanced employee awareness about construction safety measures

What are the various steps involved in the Construction Safety Audit process?

Opening Meeting with the client team

Site Visit

Document Verification

Closing Meeting with the client team

CDG -construction-safety-audit-01

Why CDG?

CDG has successfully delivered construction safety auditing services to Top Leading Companies.

Auditor Experience

A Competent team of Construction Safety auditors with more than 30+ years of collective construction safety experience will help you to identify the potential site hazards and manage the site-specific safety risks through a systematic assessment and verification process.

An Excellent end to end support to clients during Pre-audit (Understanding the objectives & scope, selecting audit criteria & audit team members, developing an audit plan, notifying the facility & reviewing the background information), On-site (Opening/Closing Meeting, identifying areas of concern, site inspection, document review, staff interviews, an initial review of findings), Post-audit (Final evaluation of findings, submit a preliminary report, get management approval & submit final report) and Follow up or review (Verify the recommendations taken on audit findings). CDG -construction-safety-audit-02

What your organization will receive from the service?

Provision of expert support and advice which can include:

Executive Summary Report for the Management

Customized construction safety audit checklist with respect to client’s business model

Detailed analysis of Observations and its Recommendations

Pictorial evidence supporting observations

Detailed dashboard tracker for multi-location audit

| Download |

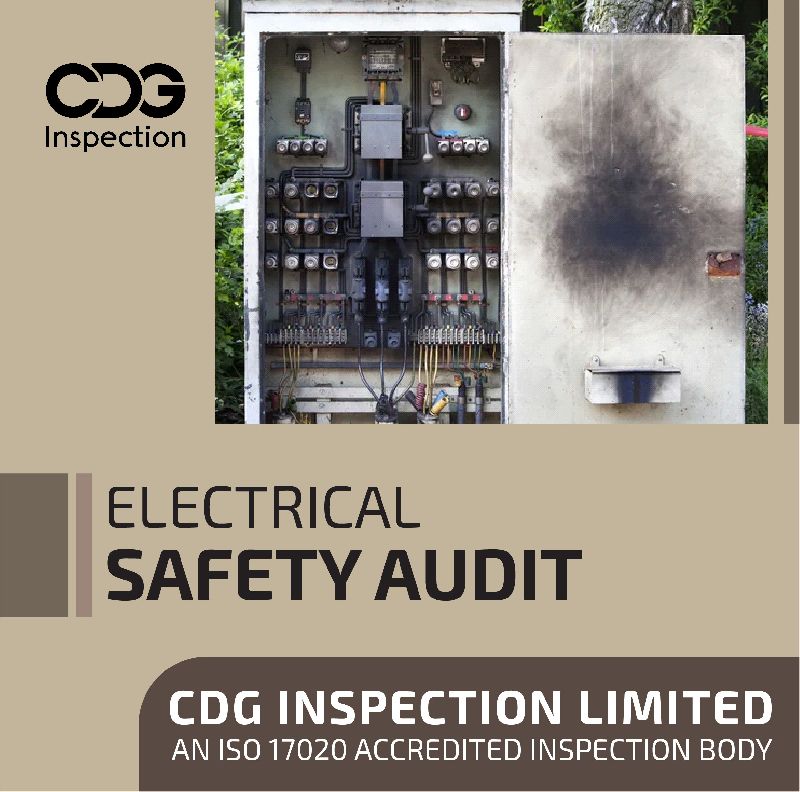

Electrical Safety Audit

CDG has been a provider of electrical safety audit services for over one decade. Our electrical safety experts, experienced engineers, and field technicians have the skills and knowledge necessary to conduct electrical safety audits for your facility. Electrical hazards continue to threaten the safety of people and property in the form of shocks, burns, injuries, fires, and explosions. With electricity having become an indispensable part of our life, electrical risks are to be managed effectively. Through our Electrical Safety Audit, we investigate if complaints and concerns by workers regarding electrical safety are substantiated and whether all other electrical safety hazards have been addressed.

We conduct electrical safety audits considering IS (Indian Standard) guidelines, IE (Indian electricity) rules, etc. Electrical Safety Audit by CDG ensures the organization's adherence to safe Electrical Installation, use of standard operating procedures of electrical intensive equipment, and following Electrical Safety Standards. CDG’s Electrical Safety Audit is best suited to organizations that require a detailed and objective evaluation of their electrical safety. Our electrical safety audit is preferred by organizations globally to benchmark their safety management system against the best international practices and legal requirements of their countries.

Electrical Safety Audit Electrical shock related to the use of electrical products is the cause of thousands of injuries and even deaths around the world each year, whether because of poor design, inadequate maintenance, or unintended use.

CDG Inspection offers electrical safety testing for all types of electrical and electronic products in our accredited laboratories or at your own site. WHAT IS ELECTRICAL SAFETY TESTING? Electrical safety testing is carried out to evaluate the potential risks of electrical shocks to customers when using their products. Evaluating a product for electrical safety usually includes the following tests: High voltage test (dielectric withstand test) - measures the ability of an electrical product to withstand a high voltage applied between a product’s electrical circuit and the ground. Leakage current test - evaluates whether the current that flows between an AC source and the ground does not exceed a specified limit. Insulation resistance test - calibrates the quality of the electrical insulation used. Ground continuity test - ensures that a clear path is available between all exposed metal surfaces and the power system ground. Benefits of this inspection: For any construction, electrical installations play an essential part. Improperly executed, it can lead to disasters.

Thus, periodic inspection leads to a reduction in the risk of fire. Following a single procedure ensures that all the standards are followed consistently and the workloads are streamlined It helps in increasing the safety of the working environment. Helps in the reduction of machine/equipment damage. Periodic inspection minimizes the danger to property, business, and the public.

CDG is a leading organization in India for Factory Compliance Audit In today’s highly competitive market, it is imperative that you build a vendor base of partners that will meet all aspects of your production needs, from design and quality to product delivery requirements. Comprehensive evaluation through factory audits and supplier audits are vital components of the evaluation process. The key criteria a CDG’s factory and supplier audit assesses are facilities, policies, procedures, and records that verify a factory’s ability to deliver consistent quality products over time, rather than at one given time or only for certain products. Major checkpoints of a supplier audit include Company legality information Bank information Human resource Exportation capability Order management The standard factory audit includes: Manufacturer’s background Manpower Production capability Machine, facilities & equipment Manufacturing process & production line In-house quality systems such as testing & inspection Management system & capability Environment Our factory audits and supplier audits provide you with a detailed analysis of the condition, strengths, and weaknesses of your supplier. This service can also help the factory to understand areas requiring improvement to better meet the buyer’s needs. Benefits of our factory inspection services ·

For Buyer: The buyer gets a detailed report of your suppliers before the finalization of the deal. Our factory compliance audit service ensures that the buyer's interest is safeguarded. Before selecting any inspection agency always ask for their accreditation status & scope. A non-accredited agency may not be efficient to conduct factory compliance inspections adequately & efficiently.

What is included in the factory compliance audit?

Analyzing the factory's operating structure, systems, machine models, procedures, and quality control. Regular performance tests, sensitive point information, machinery state, power supply, and transportation are all included. A comment about the sampling system and its capability. Information on the supply and sub-supply. Analysis of the factory's production line, equipment, tools, storage areas, packaging areas, and other shops. Having an organizational flow map and a manufacturing workflow chart for a plant.

Our expertise in 'Factory Compliance Audit'

In the field of factory compliance auditing, CDG has long been a market leader. Our factory compliance inspection service is specifically designed to meet a potential buyer's specifications. Anything from manufacturing capacities and quality management processes to staff facilities and working conditions is reviewed independently by our trained auditors. We go on location to gather the details you need to choose high-quality vendors. Factory audits will help you increase the efficiency of your supply chain while also lowering the risk of sourcing from India. With our experienced team, we will make this happen for you.

Contact CDG for Factory Compliance Audit.

WHY FIRE SAFETY AUDIT IS REQUIRED?

An independent audit is necessary for the owner of the business because of the following advantages:

• Get information about fire safety

• Identification of fire risks

• Using a plan to remedy deficiencies

• Detailed documentation of the deficiencies found

• insurance benefits are provided in the event of a fire

• Separation of responsibility for the object

• Serious, risk-oriented suggestions for remedying defects

• professional advice

• 3 years without review.

• Structural fire protection: The right building materials in harmony with fire protection

• Technical fire protection: The optimal technology for your safety in the event of a fire

• Organizational fire protection: Guarantee of fire protection in the company

There may be other reasons for the Fire safety audit. Having received the full information from the auditor, the owner has the opportunity to plan the organization's program of action. The information will help to correct deficits economically, improve security, and set up the necessary systems.

BENEFITS OF FIRE SAFETY AUDIT

A fire audit is understood as a special set of measures taken to bring the facility into full compliance with the current fire safety standards. Specialists involved in conducting a fire audit conduct routine inspections of the state of fire protection of an object - industrial or otherwise. When conducting a fire audit, the existing shortcomings and violations in the organization of fire safety are revealed.

The benefits of a fire audit can be summarized as follows:

- Based on the results of the fire audit, the real impact of the fire protection system on fire safety is calculated, which allows you to choose the most effective and profitable ways to protect without wasting costs.

- increasing the level of protection of the population, territories, property of legal entities, and individual entrepreneurs.

- reducing the administrative burden on business entities as a result of their withdrawal from the "service" sector by state supervisory authorities.

- exemption of fire authorities from control at insignificant objects, focusing their efforts on objects with a massive presence of people, potentially dangerous and socially significant objects;

- taking into account the results of risk assessment when assigning the amounts of insurance fees and their differentiation depending on the level of security of the facility.

- ensuring transparency of procedures for exercising supervisory functions, preventing manifestations of corruption in this area of activity.

The audit company does not stop the activity, does not fine the customer for violations, but on the contrary, helps to find the optimal solution for the owner within a reasonable time frame;

Thanks to preventive and targeted safety measures, a fire safety audit recognizes the risks at an early stage and does everything in its power to avoid potential damage. It develops risk-appropriate fire protection concepts and supports you in choosing the appropriate structural, technical, and organizational measures. Our services are individually tailored to your property or company, the concept is created according to your needs and situation.

PROCESS OF FIRE SAFETY AUDIT in CDG:

- A fire audit is usually carried out in several stages. In the beginning, an agreement is concluded for its implementation, which describes in detail all the actions of the specialists conducting the audit and the expected results. The service of conducting a fire audit can be offered only by specialists of an accredited organization

- The procedure for conducting a fire audit includes analysis of documentation, an actual inspection of facilities, expert assessments, and calculations of possible risks. A fire audit is carried out for any objects, regardless of their size and functional purpose.

- The audit firm draws up an action program and organizes a group of experts. Then specialists visit the site to assess the fire safety risks.

CDG Inspection Ltd aims to deliver a complete solution that is suited to your company's specific requirements with GDP audit services from Gurgaon, Haryana. We may undertake pharmaceutical audits of your facilities, as well as any contracted warehouses and shipping businesses, in accordance with GDP guidelines.

A complete service that is adapted to your company's requirements. As per the standards of Good Production Practices and Good Distribution Practices, we audit manufacturing facilities (solid dosage, dermal fillers, lotions, salves, liquids, and APIs), associate offices, and outsourced warehouses.

Our auditors organize and conduct audits by designing, managing, and tracking audit schedules. We generate audit reports (in IPS or client report formats), track observations using CAPA, and close the audit.

Good distribution practices (GDPs) are required by regulators in most regions A GDP audit helps ensure that the products you are storing and transporting are safe for human consumption. It requires knowledgeable professionals to make a dedicated effort to ensure policies and procedures are in place and enforced.

Audit Management in Distribution:

1. Planning the Audit:

2.

a) Evaluation of the distribution chain/ Risk-based

b) Planning, Audit planning, and resource planning

c) Auditor training and qualification

3. Conducting the Audit:

4.

a) Aide Memoire vs. Checklist (benefits and risks)

b) Audit strategy during the audit

c) Audit report and classification of findings

5. Audit Follow-Up:

6.

a) Follow-up of corrective/ preventive actions (CAPA)

b) Development of Key Quality Performance Indicators(KQPI)

c) CAPA efficiency evaluation in the follow-up audit

7. Auditing and Qualifying Service Providers:

8.

a) A look behind the scenes: what can go wrong

b) Challenges, that can occur while auditing.

c) Examples and possible solutions

Benefits of GDP Audit Services:

1. GDP Audit Service is a useful indicator of a nation's economic performance, and it is the most commonly used measure of well-being.

2. Identify operational inefficiencies and waste.

About the Company:

CDG is a truly global provider of Technical Inspection, Verification, Testing, and Conformity Assessment for Industrial Markets. The core values of complete independence, transparency, and integrity guide us in our mission to deliver first-class services on a constant high-quality level to customers around the world. Our Teams of Engineers ensure that the quality and performance of products or installations meet applicable requirements, whether they are regulatory, voluntary, or client specific. CDG is a leading third-party inspection agency in India. A Third Party comes in between the Purchaser & Supplier to ensure the services required by the first and second parties are met and in order with terms of references.

CDG Inspection Ltd provides GHP audit services from Gurgaon, Haryana. Certification by GHP (Global Health Professionals). GHP (Good Distribution Practices) is a set of guidelines that specifies the circumstances in which items should be manufactured.

Requirements for a Good Hygiene Hygienic requirements, expressed as GHP, are related to the design and configuration of hygienic food production facilities, cleaning and disinfection methods, food processing in raw foods is microbial quality, hygienic operation of each processing step, and personnel hygiene is a system that includes applications such as. Foodborne illness can be prevented by following proper food hygiene standards, which are required to assure the safety of food from farm to fork.

GHP stands for Good Hygiene Practice, and is a key step in food chain hygiene management within the whole food supply chain and ensuring the food is safe and suitable for consumption. It touches on multiple aspects of the food industry, including the food supply chain, sanitation facilities, workers’ hygiene practices, pest control, and preventing physical and chemical pollutants.

Medical hygiene:

Medical hygiene pertains to the hygiene, practices related to the administration of medicine, and medical care, that prevents or minimizes disease and the spreading of disease.

Body hygiene: Body hygiene pertains to hygiene practices performed by an individual to care for one's bodily health and well-being, through cleanliness.

Culinary hygiene: Culinary hygiene pertains to the practices related to food management and cooking to prevent food contamination, prevent food poisoning and minimize the transmission of disease to other foods, humans, or animals. Culinary hygiene practices specify safe ways to handle, store, prepare, serve and eat food.

Personal service hygiene: Personal service hygiene pertains to the practices related to the care and use of instruments used in the administration of personal care services to people, Personal hygiene practices include: Sterilization of instruments used by service providers including hairdressers, aestheticians, and other service providers. Sterilization by instruments used in body piercing and tattoo marking. Cleaning hands.

Food hygiene: There are some essential principles of food hygiene to achieve the goal of ensuring that food is safe and suitable for human consumption.

Food safety: Assurance that food will not cause harm to the consumer when it is prepared or eaten.

Food suitability: Assurance that food is acceptable for human consumption.

Areas examined under GHP

1. Primary production

2. Establishment: design and facilities (Design 1)

3. Control of operation

4. Establishment: maintenance and sanitation (Design 2)

5. Establishment: personal hygiene (Design 3)

Primary production: Hygienic practices should reduce the likelihood of introducing hazards that may be difficult or impossible to control at later stages of the food chain

Establishment: design (1): Premises, equipment, surfaces, and facilities should be located, designed, and constructed to ensure: minimum contamination proper maintenance, cleaning, and disinfection protection against pests.

Establishment: design (2): Evaluation of the premises takes into account: Location, Equipment Facilities, water, air, lighting, and storage.

Establishment: personal hygiene (Design 3): Good housekeeping” applies to the surroundings and the roof of the establishment Pest control starts at the boundaries of the premises Water management deals with incoming and use water. “Dry zones are designed to remain dry Drains can be cleaned Cable trays carry cables, not dirt or dust Only potable water is in contact with food Air handling systems deliver the required air quality (and not contaminants) Doors are closed when not used.

Understanding and implementing good manufacturing practices (GMPs) in a food manufacturing facility will help to prevent situations that could lead to customer illness and or even death

So let's talk about GMPs

The GMPs or good manufacturing practices are practices that help to ensure food is produced in a clean and safe environment

GMPs are practices to obtain safe and quality products and what is considered a safe product

A safe product is a product that is not going to cause any harm to the consumers when the food is prepared and or eaten according to its intended use

Now what we have here is a complete list of the current good manufacturing practices required in a food manufacturing facility

Today we will only be focusing on the GMP's rules that are within your control to manage, personnel practices, and general requirements

- Personal hygiene

- Clothing and personal equipment personnel practices

- Disease control

- Cleaning and sanitation and pest control

GMPs are the foundation of the food safety management system. GMPs are the basics we need to know and perform to keep food products free of adulteration. Good manufacturing practices aim to protect the product from any microbial chemical or physical hazards that may cause it to become unsafe or unfit for the purpose

The GMPs are mandatory for everyone working in a food manufacturing facility. It’s everyone's responsibility to guarantee that products are produced in a clean and safe environment to prevent contamination of the food

All employees, contractors, and visitors will need to comply with GMPs

Okay let's talk about the personal hygiene

Germs are present on human skin, hair, under fingernails, dirty clothes, and in the mouth and nose. The company's personal hygiene practices are an important way to reduce the risk of contamination; as I mentioned before whether employee or not, everyone should comply with the following practices that help to minimize bacterial contamination

- Daily showers or bathing

- Change into clean clothes

- Trim and clean fingernails

- Shave or wash the beard and wear a mask, and have a good dental hygiene

- The hands are the major source of contact between food and food industry workers

Employees shall keep their work area and equipment always clean and sanitized. Areas such as florist drain walls, table tools, and conveyors. Only approved chemicals and approved cleaning tools should be used and always place utensils and chemicals in their designated area

All chemical products sanitizers, cleaners, lubricants, and solvents shall have a label that identifies the content in the container. It is not acceptable to have containers without a label and make sure to keep updated SDS on file

Pests are a source of both microbial and physical contamination. It’s the employee's responsibility to ensure all doors remain shut when not in use

Any signs of pest activity must be reported to the supervisor. Information about pest citing will be passed on to the pest control contractor

If all the practices we talked about are not well implemented it can cause outbreaks and get people very sick and die and the company can face legal consequences including costly fines and if the outbreak has a devastating effect, possible shutdown

CDG Inspection Ltd provides green audit services around the country to guarantee that your companies and vendors comply with national and international standards or industry best practices in terms of protecting the environment.

We can assist with the formulation and maintenance of a detailed plan to assist the deployment of continual improvement processes, based on your company's goals. The initial evaluation can be supplemented with training, supervision, coaching, and certification options that are suited to each facility's needs.

Our detailed audit reports can advise clients on how to avoid pollution and save money on raw materials by using cleaner production practices, both in the initial stages and in the long run.

Environmental audits are systematic and objective assessments of the environmental status and performance of properties, facilities, processes, and/or operations. They are a valuable management tool that can be used to identify and assess environmental problems and initiate corrective actions which ensure compliance with applicable environmental laws and regulations and internal management policies and practices. Environmental audits also can be used to assess the quality of the existing environmental management systems, and to foster additional initiatives to improve the environmental performance of a facility. Environmental audits are reviews of a company’s operations and processes for the purpose of assessing compliance with environmental rules and regulations.

The Honourable High Court, therefore, thought in the interest of Justice to introduce the Environment Audit Scheme where qualified technical professionals would become a link between the individual industries on one hand and the GPCB & other public authorities as well as the association of industries on the other hand; with the added vital elements of accountability and transparency.

CDG has expertise in conducting environmental reviews and audits of organizations. The scope of the review can be as broad or as narrow as your requirements: from initial environmental reviews of entire organizations to waste compliance audits, feasibility studies, and odor reviews. We can help our clients by conducting Environmental Audits as per the guidelines of State Pollution Control Boards. Our systematic audit reports can provide clients with guidance on measures to prevent pollution and save raw material costs through cleaner production techniques both at the primary stage and for an ongoing operation. Our Environmental Audit procedure encompasses Pre-Audit Activities, Activities on Site, and Post-Audit Activities which effectively become a vital tool to provide our clients with an objective evaluation of how well the operation management systems are performing.

What to Expect from the Green Audit Process:

An auditor will arrive at your faith community at a scheduled time. CDG members and staff are encouraged to participate and gain hands-on insight into the process and the opportunities. Where feasible, a blower door unit will be used to depressurize the building to help identify air leaks. Our auditor will walk around the building outside and inside, room by room, and look at:

where energy efficiency could be improved,

where potential air quality concerns are,

where water resources could be saved,

where waste could be diverted, and

where operations of the building could be improved to save money and effort.

Safety auditing is a core safety management activity providing a means of identifying potential problems before they have an impact on safety

A safety audit is a general term used to describe an activity where the facility gathers information about one or more aspects of the workplace to evaluate the risk levels for health or safety issues

HSE audit assessment of an organization's health and safety policies systems and procedures primarily audits enable you to protect employees and customers from harm

What are the types of audits?

Internal audit

External audit

What are internal audits?

That is normally performed by the internal team to evaluate the current state as an effect of a management system

What are external audits?

It is the second type of audit which is usually conducted by a third party to evaluate and examine the effectiveness of the current management system

What are the sources of evidence auditors look for

1. documents and records

Examples; method statements, HSE policy procedures, training records, maintenance records, inspection records, risk assessment, incident records, civil claims, accident investigation reports, statutory examinations records, etc.

2. interviews of workers and management

3. direct observation of the site activity and behavior of individuals

The steps to carry out an audit

An audit is carried out in three steps

1. priority preparations

Auditors use three methods to gather factual information

One; the scope of the audit

Will it cover just health and safety or environmental management as well?

Two; the area of the audit

Will it be just one department or all departments?

Three; the extent of the audit

The fully comprehensive audit which may take weeks or more selectively for who will be required

Auditors will need to be accompanied during their visit and will need access to managers and workers for information gathering

Five; information gathering

It is common practice for auditors to ask for copies of relevant documentation before starting the audit so that they can prepare what is needed during the audit

Auditors use three methods to gather factual information

One: reference to paperwork

The documents and records that indicate what should be happening and what has happened; relevant to a particular issue

Two: interviews

Word-of-mouth evidence was given by managers and workers

Three: direct observation of the workplace equipment activities and behavior

What is the end of the audits?

Verbal feedback or presentation to the management team is usually provided at the end of an audit. This verbal feedback will be followed by a written report

The report will make a recommendation for improvement and indicate priorities and timescales

The importance of conducting a safety audit

Organizations conduct safety audits to comply with laws or regulations and to provide a safe workplace for everyone

A safety audit identifies different levels of risk in each work area of an organization

One identifies the risks and levels of those risks within the workplace

Two; to identify strengths and weaknesses in your safety procedures

Three; assess whether your safety procedures are legally compliant

Four; compare current documentation and practices against best practices and legal obligations

Five; recommend improvements in your safety procedures

Six; ensure that there are adequate resources available to manage OHS and

Seven; ensure that the resources devoted to health and safety are being utilized effectively.

CIL provides workplace safety audit services in Pune, Maharashtra ,India. CIL is an ISO 17020 accredited inspection agency.

CDG Safety Audit Consultants have extensive experience and technical expertise that is highly valued in the industry. At CDG, we don’t just practice and deliver health and safety services for our clients, we also provide them with highly relevant and up-to-date education and training.

Our Service Include

– Safety Audit

– Electrical Safety Audit

– Fire Safety Audits

– Risk Assessment & HAZOP Study

– Safety Training

OBJECTIVES OF AN INDUSTRIAL SAFETY IMPROVEMENT AUDIT

The overall objectives of the safety audit were as under: -

1. to carry out a systematic critical appraisal of all potential hazards involving personal, plant, services and operation methods.

2. to examine critically the working conditions of the plants which are hazardous in nature and may lead to accidents.

3. to evaluate work practices and procedures followed in the plant and their effectiveness.

4. to evaluate the effectiveness of the existing safety and health management system and suggest recommendations for implementation by the management.

SCOPE OF INDUSTRIAL SAFETY AUDIT

The scope of the safety audit is limited to the safety and health of workers employed in the manufacturing processes and operations and also the safety of the plant and equipment used in the factory.

The Audit is carried out as per the requirement under IS 14489 and the various Legislative requirements such as the Factories Act, 1948 and the state Factories Rules, Environment (Protection) Act, 1986 and Rules made there under and other applicable Statutes. “Management Systems” audit is done to assess the management’s involvement and commitment towards promoting safety and health systems at work. Management system audit provides scope of examining and evaluation of safety policies and procedures and their review, hazard communication system, dissemination of information and hazard awareness programs, training and motivation of employees, etc.

Besides management systems audit, technical aspects of plant activities namely, storage and handling of hazardous substances, Emergency Preparedness, process and operational safety review, transportation safety, testing and examination of plant and equipment, housekeeping, waste disposal system, fire prevention and control, etc. would also be audited.

STANDARDS TO BE FOLLOWED

The audit is conducted with the following standards and codes of practices on Safety and Occupational Health:

I) Indian Standard on Codes of Practices for Occupational Safety & Health Auditing (IS 14489:1998)

II) Legislative Requirements (The Factories Act, 1948, the Explosive Act, 1884, the Boilers Act, 1923 and the Environment (Protection) Act, 1986 The SMPV rules, The Gas Cylinder Rules, the Electricity Act and Rule, the Mines Act and Rules etc.

III) Current Safe Practices, Prevalent in the factories and mines and the company internal controls.

Benefits of Safety Audit are:

It will contribute to your compliance strategy going forward, which in turn will assist you in providing a safe working environment, boost employee morale and increase productivity.

OBSERVATIONS & RECOMMENDATIONS

A detailed Recommendations/Action Plan is prepared based on the ‘Audit Findings’. The action plan contains an implementable schemes/ best practices / technology/ innovative solutions for improving Electrical, Fire, Occupational & Health Safety, Emergency Preparedness and Response Plan measures to be followed by the industry as per Short Term, Medium Term and Long-Term Period.

CDG Inspection Ltd, in Gurgaon, Haryana, offers a proven approach that can help you enhance safety, minimize occurrences and injuries, and boost confidence amongst your team, whether you choose to understand how serious your workers take the protection and just want to understand how protected they experience in your workplace.

We'll conduct a thorough safety audit to assess the effectiveness of your program, discover compliance issues, and recommend solutions. Our industrial safety audit services would be tailored to your individual activities, allowing you to take action, eliminate hazards, and establish the next steps to meet your safety objectives. You'll have the data you need to make important decisions, as well as a benchmark against which future safety measures can be measured.

5 Important Steps to an Effective Safety Audit

An effective Safety audit is one that has been proven to ensure that the business has a safety program in place to reduce incidents and mitigate safety risks to their workers. Most importantly, “in place” means policies and procedures that have been tested, trained, and demonstrated in practice, as evidenced by the audit program. The 5-step safety audit steps below outline provide a management summary and structured approach toward the development of an effective safety audit.

Step #1: Audit Planning

worker in safety vest at job site safety audit is a form of test, and therefore, a test plan needs to be established prior to test execution. The key components of an Audit Plan are the basic documentation of the: “who, what, and where.”The planning step is the key to the entire process since the audit plan defines the procedures and sets the safety test baseline.

Step #2: Audit Execution

With a trained team identified, scope and baseline documentation defined, the next step is to conduct the audit as planned. The baseline documentation is used to effectively compare written procedures to activity in the workplace. Variations from established safety procedures are documented, along with observations of the actual work conditions, and any important input from the workers involved.

Step #3: Compile the Audit Report

safety leader conducting safety audit After conducting the audit, the audit team will integrate test results and information into a concise audit report. Part of the team’s training is to ensure a well-documented report that details any variances to the audit baseline and important audit findings and describes things that are working well in addition to any problem areas. Problem areas or negative findings are addressed in the recommended actions section of the audit report to start the process improvement efforts needed.

Step #4: Set Corrective Action Plans and Process Improvements in Motion

The audit execution and report go beyond a simple pass/fail approach. The findings should contribute to the continuous process improvement effort towards optimal workplace safety. Audit findings may identify significant corrective actions that need to be immediately set in place for worker safety, but most often baseline variations and input from the workforce are addressed as part of continual improvement activity. Process improvement follow-up would include prioritizing tasks, with assignments and suspense dates.

Step #5: Communicate Results

assessing the site during a safety audit. An effective workplace safety audit is essential to business continuity, employee protection, and morale, along with the requirement to demonstrate compliance with all guidelines. It is important that all employees have a transparent understanding of the audit, and their safety status. Workers have been trained in safety procedures and adherence to those procedures is essential in reducing workplace incidents.

The supplier audit services provided by CDG Inspection Ltd will assist in ensuring that the desired processes and procedures for reaching compliance are followed. We are based in Gurgaon, Haryana. We will compile the audit findings and submit a comprehensive performance report to both the client and the supplier.

As a result, they are frequently tailored to the needs of the company. These statements, however, only give a limited level of certainty. As a result, a chain of custody control should be a key component of any REACH compliance approach. In addition, to reduce risk and costs, a balanced approach to supply chain engagement and involvement, backed by audits and monitoring, must be developed.

A supplier audit inspects a supplier’s usage of industry regulation practices, including health and safety and correct manufacturing processes. Generally, auditing a supplier covers a large area with several practices. Therefore they are usually bespoke to the client’s requirements. The supplier auditing process can differ for each industry, from food to electrical goods.

As companies grow the size of their supply chain, selecting the appropriate supplier is essential. A supplier’s reputation and quality will ensure that business runs smoothly and reduce potential issues or risks. Because of this, an audit of suppliers is essential to help in the decision-making process.

Some of the benefits of implementing a supplier audit are:

1. The Audit Reveals Potential Risks, A supplier audit can review all production processes, including shipping, manufacturing, and quality. They may give insight into gaps and check if these will cause any issues with the delivery to a client. Therefore potentially mitigating delays or deformities in the product.

2. Improves Customer Satisfaction, An organization relies on its reputation with customers. This is done through the quality of the products put forth to them. Implementing strong standards and ensuring a supplier follows them allows for customer satisfaction to be upheld. A supplier audit can assist in the quality control processes of a supplier to potentially mitigate any product quality or safety issues. It is also a way for an organization to measure the supplier’s performance.

3. Helps Build Communication With Suppliers

A supplier audit is also a way to improve and maintain strong communication with a supplier. Clear visibility and understanding of suppliers’ activities can assist with improvements and the business relationship. Regularly scheduled audits ensure objectives are met and can be constantly developed depending on the organization’s needs.

We at CDG provide a range of high-quality supply chain innovations and solutions, including supplier audits. With over 25 years of experience within the quality control industry. We understand the importance of clear information for organizations to make valuable choices. Contact us to learn more about our supplier audit services and how we can help your organization with its supply chain needs.

When supplier audits are conducted, an organization follows a procedure to consistently measure supplier quality and compliance. This is recorded in a supplier audit report. This report contains all the details of the audit, this includes:

Details of the factory, including the key team and location.

A summary of the audit results.

Key attention points provide more details regarding faults and general comments.

A list of follow-up suggestions to improve the supplier.

A full audit list includes general information and all the detailed inspection findings that work on an ABC quality scale.

Finally, a section for images taken whilst on location provides evidence of any faults.

Based in Gurgaon, Haryana, CDG Inspection Ltd is a supply chain audit services leader with a long history of offering end-to-end services that help businesses manage supply chain threats and protect their reputation. Collective justice, security, safety, the environment, and longevity are all significant concerns in the global supply chain, and Supply Chain Assurance solutions address them.

Our end-to-end risk assessment auditing, training, and technology solutions, which are driven by big data, look at the full value chain to give contextual information to a Corporate Responsibility Program, ability to make company choices, and build a culture of engaged suppliers who comprehend, share, and illustrate your brand.

As supply chains grow increasingly complicated in the modern world, it is vital that companies utilize supply chain audits to stay on top of the multitude of risks that sprout from various points. Organizations that use supply chain audits have the opportunity to boost customer service, reduce operating expenses by decreasing the purchasing cost, decrease production expenditure, increase profit, decrease fixed assets, and increase cash flow.

Companies can also verify through an unbiased party that certain levels of excellence are maintained throughout the entire supply chain using a supply chain audit. In the modern world, it is imperative that integrity and continuity are maintained for an organization to succeed.

Can you ensure that your products always have consistent quality, Is your shipment strictly in accordance with the customer's specifications, CDG will inspect your products, processes, service quality, and shipments to ensure that your products are of consistent quality and service standards?

OUR SUPPLY CHAIN AUDIT SERVICES

At CDG, we view supply chain audits as an opportunity to uncover the areas of business development that are not up to standards and tackle them head-on. We not only aim to provide a comprehensive overview of supply chain management but identify key actions that will boost productivity and alignment. Well, help you identify the gaps in productivity and efficiency of suppliers.

Investing in a supply chain audit with CDG is an investment in a partnership for life. CDG has an international reputation as an independent and impartial technical service provider. We assess each project objectively and with absolute expertise so that you can base decisions on unfiltered information. Our experts have the multidisciplinary know-how to help you resolve complex challenges across international supply chains.

The benefits you get from supplier audits

Assurance that partners and suppliers share your high standards for quality and safety

Reliable audits designed and carried out by interdisciplinary experts

Easy, straightforward vetting of potential partners

Proven quality to earn customer and consumer trust

Our services include initial supplier audits and continuous monitoring. We provide you with the expertise you need in deciphering international, national, and local regulatory requirements. We are experienced and equipped to carry out audits in a variety of fields including,

Environmental health and safety

Data privacy and information security

Quality management systems

Supply Chain Audits according to the highest international standards and customer programs.

In the increasingly complex world of commerce, we from CDG see ourselves as reliable companions. We are an expert partner for auditing, evaluating, and certifying the behavior of suppliers in terms of these key factors for a successful company,

fair and safe working conditions

responsible business practices

ecological and economic sustainability

CIL provides workplace safety audit services in Kolkata, West Bengal, India. CIL is an ISO 17020 accredited inspection agency.

Safety audit begins with self-appraisal by an individual employee. He is encouraged to check his credentials against unsafe act committed knowingly or unknowingly. The factory carries out its internal safety audit since they are well aware that an accident or dangerous occurrence retard productivity adding to the loss whereas an accident-free period has become a marked value-addition. They adhere to the golden principle of “A Penny Saved is A Penny Earned”. The society, too, has risen to an accident-free environment. They have whistle blowers and non-Government organizations armored with the latest “Right to Information (RTI) Rules. Various statutory authorities in India are also equipped with state-of-the-art hardware and software to monitor and identify any malpractices leading to accidents and dangerous occurrences. For instance, satellite imagery, at once, reveal where there is smoke in the sky and brown water gushing into streams and rivers.

External safety audits and internal safety audits have their own intrinsic qualities. An internal safety audit, carried out by a committee constituted from experienced experts of a factory, reveals most unhidden unsafe acts and unsafe conditions. After-all, the occupier and its employees know better than others about conditions in their factory. An external safety audit, carried out by experts constituted from other factories, academic professionals or those registered with the DGFASLI brings out a non-complacent, un-corrupted, perspective report coupled with benchmarked solutions and advice.

The objective is to carry our systematic critical appraisal of all the potential hazards involving man, machine and material which also embodies in itself plant services and method of operation. In general, the objective is to cover the examination and qualitative assessment of all facets of safety in every activity which includes research and development, design ad layout, occupational health and hygiene, environmental feature ad control, plant, product and process safety, employee and public safety. It involves a review of safety and health aspect in the production, technical operation, maintenance, clearance certificates, emergency procedures, job description, operating instructions, training, housekeeping, personal attitude, management-worker relationship, workers’ participation in health and safety matters etc.

FACILITY SAFETY AUDIT

Visit site to assess physically the safety status including housekeeping.

A safety audit well executed, and follow-up safety measures religiously adopted would spontaneously result in achieving a healthy index of the factory. A safety index is the ratio of the safety status of the previous year and the current year. This index would be less than 1. The more a factory is concerned about the safety, occupational health of its employees and the environment upkeep, the lesser and healthier would be the safety index.

SAFETY SYSTEMS

a) SAFETY FUNCTION

· Role of safety vis-à-vis other functions

· Procedure governing safety at works

· Training given to safety personnel/other employees

b) SAFETY INSTRUCTION

· Works Standing Instructions

· Area Instructions

· Statutory Warnings/Instruction

c) DOCUMENTATION

· Manuals (Safety/Fire/Others)

· MSDS

· Audit

· Statutory Compliance

d) AUDITING/INSPECTION

· Safety auditing

· Inspection of safety features

· Frequency

· Agencies utilized (in-house/external)

· Action arising from audits

e) COMPLIANCE

· Status of compliance with regulation

· Register of compliance

· Monitoring

Contact CDG for Audit and Inspection.

CIL provides workplace safety audit services in Mumbai, Maharashtra , India. CIL is an ISO 17020 accredited inspection agency.

CDG is one of the leading Independent Third-Party Safety Audit Companies. Our safety audits are considered as a management tool and being conducted by competent Safety Auditors.

The audit identifies the areas of strength & weakness and provides a structured approach to continual improvement.

Our quantified assessments are used by global organizations to benchmark their safety management system against international best practices and country legal requirements.

Safety Audit of factories involved in hazardous processes and dangerous occurrences, has established itself in India. The entire credit goes to the 1987 amendments in the Factories Act, 1948 that we know as Chapter IVA prescribing provisions relating to hazardous processes.

It was the 1984 Bhopal disaster that took 16000 lives and crippled more than 500,000 people which prompted a serious review of existing safety enactments. Safety Audit has now become one of the spearheads to bring about a safe and healthy environment in industrial establishments.

In the years that has passed since the tragic Bhopal incident, the accident rate, the rate of dangerous occurrences and hazardous disasters have come down drastically. While the production and productivity are touching new heights with their graph always pointing upward, this achievement becomes more pronounced. The cut-throat globalization and competitiveness have changed the definition of accident from “freedom from risk or danger” to “acceptable level of risk”.

Safety Audits – What you will get

Upon completion of the audit process, a detailed report is prepared by the CDG auditors and is issued within two weeks. The report content generally includes:

Executive summary including graphical performance indicators & noteworthy efforts

Overall and segmental rating/scoring (applicable for protocol assessment)

Findings & recommendations for improvement

Action plans

Photo gallery

Key Benefits of Third-Party Audit-CDG

Verification of the effectiveness of your occupational health and safety (OHS) management system

A comprehensive audit report outlining the findings of the audit, quantified outcomes, associated areas of improvement with detailed recommendations

Improved safety performance, workforce morale and well-being

Potentially reduced rates of accidents, injuries, ill-health, litigation costs and improved productivity

Experience sharing of the industry leading and trained safety auditors

To ensure health and safety compliance we follow these three steps:

- The Health & Safety Audit is carried out by an experienced and fully qualified CDG Consultant. The Consultant will:

- Assesses the extent to which your company complies with the relevant legislation.

- Reviews your organization's health & safety policies, arrangements and management systems.

- Covers the requirement to manage health & safety risks as detailed in HSE guidance.

2. Following the Audit, we carry out a Workplace Health and Safety Inspection, which includes:

- A comprehensive inspection of the workplace.

- An overview of health & safety compliance.

- Advice and guidance on compliance with legislation and best practice.

- Speaking with employees where appropriate.

3. Findings and recommendations from the Health and Safety Audit are recorded in a comprehensive report, which includes:

- An executive summary with prioritized findings and recommendations.

- An Action Plan covering all findings and recommendations.

- Photographs.

- Management Audit Checklist

- Workplace Inspection Checklist

- Health and Safety Audit Document.

These audits can be done to attain ISO 45001:2018 / ISO 14001:2015 or for any general purpose like for submission to Client.

Contact one of our CDG Occupational Health and Safety Consultant for more information.